All services

Showing 177–192 of 267 results

-

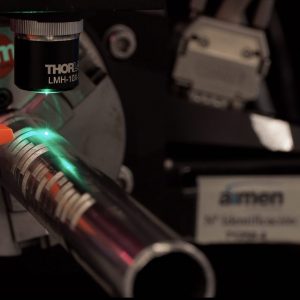

Onsite experimentation services in the field of laser-based micro manufacturing for micro Additive Manufacturing

Read more -

Onsite experimentation services in the field of micro manufacturing (micro- drilling/cutting/welding/machining)

Read more -

Operator of the Future

Read more -

Optimization of AI Models Deployments in the cloud-edge continuum

Read more -

Optimization of energy consumption in industrial environment

Read more -

Optimized vision based systems for manufacturing applications

Read more -

Palletising/de-palletising

Read more -

Performance Evaluation of Artificial Vision and Perception Systems used for automatic Identification in industrial processes

Read more -

Photorealistic 3D scene reconstruction from pictures and point clouds usable for accurate remote inspection

Read more -

PILOT Project

Read more -

PoC development support for manufacturing technologies

Read more -

Position measurement and tracking system

Read more -

Preparation of orders

Read more -

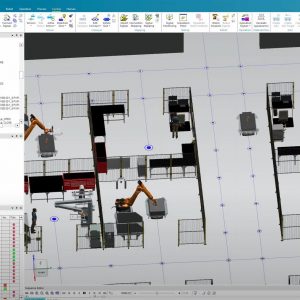

Product Digital Twin

Read more -

Production Planning

Read more -

Proof of concept with state-of-the-art equipment available at the Node.

Read more