Consortium member

Spain

The Spanish Node is coordinated by TECNALIA Research and Innovation centre. TECNALIA is part of the Node together with AIMEN-Technological Centre-, ITA- the Aragón Institute of Technology- as well as AFM- the Spanish Association of Manufacturers of Machine Tools and cluster for advanced and digitalmanufacturing, which represents the industry’s interests.

The Spanish Node envisions the creation of cutting-edge testing and experimentation facilities, based on AIsolutions for the manufacturing sector, to support companies and technology providers to:

Evolve their manufacturing processes by means of a new paradigm for automated, digitised and flexible production with the support of the most advanced AI solutions.

Apply these solutions to the new processes emerging in a circular economy (efficient use of resources, eco-design and energy efficient products, efficient processes, design for circularity disassembly, remanufacturing, recycling, etc.) that will play a key role in the future of manufacturing industries and in the society in general.

Node members

Tecnalia: coordinator

AFM: member

AIMEN: member

ITA: member

Node members

Fraunhofer IPA

- Leading the German node

- Part of Fraunhofer organisation

- Fraunhofer is biggest applied research organisation in Germany

- Fraunhofer IPA focusses on manufacturing and automation

Lead contact

Dr. Björn Kahl

bjoern.kahl@ipa.fraunhofer.de

Institute of Electrical Energy Conversion (IEW)

- Part of University of Stuttgart

- Research focus on electrical machines and contactless energy transfer

- Applications in the areas mobility, medical technology and industrial applications

Lead contact

Urs Pecha

urs.pecha@iew.uni-stuttgart.de

Research Campus ARENA2036

- Research campus with over 50 partners from industry and science on one platform

- Focused on research in production and mobility

- Establishing services with robotic infrastructure for AI applications

Lead contact

Frederik Wulle frederik.wulle@arena2036.de

Physikalisch-Technische Bundesanstalt (PTB)

- National metrology institute

- Founded 1887

- Today: 3 sites, staff: ≈ 2000

- Agency of Federal Ministry for Economic Affairs and Climate Action

- Division Precision Engineering focus: manufacturing metrology

- Virtual instruments (dig. twin), Testing of algorithms for CMM

Lead contact

Dr. Harald Bosse harald.bosse@ptb.de

Strategic equipment of the node

Main equipment

- Data capture and analytics Labs.

- AI and robotics for fluid and flexible production testbeds. Robotics development platforms.

- Additive manufacturing Fab-labs (e.g. binder jetting with industrial capacity -singular equipment-).

- High Performance Computing and advanced simulation packages.

- Advanced Composite cells.

- Artificial vision, perception systems and Labs.

- Power electronics and systems lab.

Planned infrastructure deployment

Our Node plans strategic investments to complement the already existing equipment with new one for the provision of new and most advanced added-value services.

Node services

1. Factory level optimisation

- Optimisation of manufacturing processes and plant management systems.

- Deployment of hardware and software solutions in advanced manufacturing environments.

- Modelling and simulation for the development of software solutions and algorithms in virtual environments.

2. Human robot interaction

- Autonomous, flexible and collaborative robotics.

- Support to the development and provision of high value-added data.

- Validation of AI algorithms for different virtual and physical manufacturing environments.

We test and experiment AI-based solutions, deployed in physical and digital infrastructures in different sectors and areas of interest.

3. Circular Economy

- Circular economy applied to materials and products.

- Energy efficiency.

4. Other emerging and enabling Technologies

- Benchmarking of off-the-shelf solutions.

- Regulation / testing of solutions in regulated environment.(sandboxes)

- Material transformation processes, Additive manufacturing and composites.

Our enabling technologies are: Additive manufacturing laser systems, computer vision, perception systems, digital twins, distributed computing, HPC.)

Node illustrative services

Factory level optimisation by ITA

Online quality control and tuning system based on IA.

Detection of imperfections on the surface of sheets during the stamping process.

On-line quality control and tunings system based on expert systems (machine learning, deep learning) and artificial vision techniques, which can be directly integrated into the production line process, considering the variability of the environment in terms of lighting conditions and subject to vibrations.

Expert systems or models based on learning techniques are a solution to overcome the inherent limitations of traditional inspection and quality control solutions by combining the automatic learning of a human (developed cognitive ability) with the speed and repeatability of an electronic system.

Perception and artificial intelligence for on-line inspection.

Robot based services to manage elements currently excluded from automated systems in warehouses (for reasons of volume, weight or disparity)

Collaborative robotics by TECNALIA

- Logistics centres (e.g. pharmaceutical sector handle 85% of products through traditional automation. The remaining 15% of the products are handled manually, due to the variability in size and weight (high-mix/low-volume) of the boxes. There is currently no solution on the market that addresses this situation without costly investments to modify existing warehouses.

- MAIRON has thus emerged as a response to this problem. It combines a number of advanced technologies such as collaborative robotics, autonomous navigation, advanced perception systems, teleoperation and AI-based decision making to offer a robotic solution for the logistics of packages up to 20 kg. This enables fast and efficient customer set-up and maintenance.

- Experimentation services already in place.

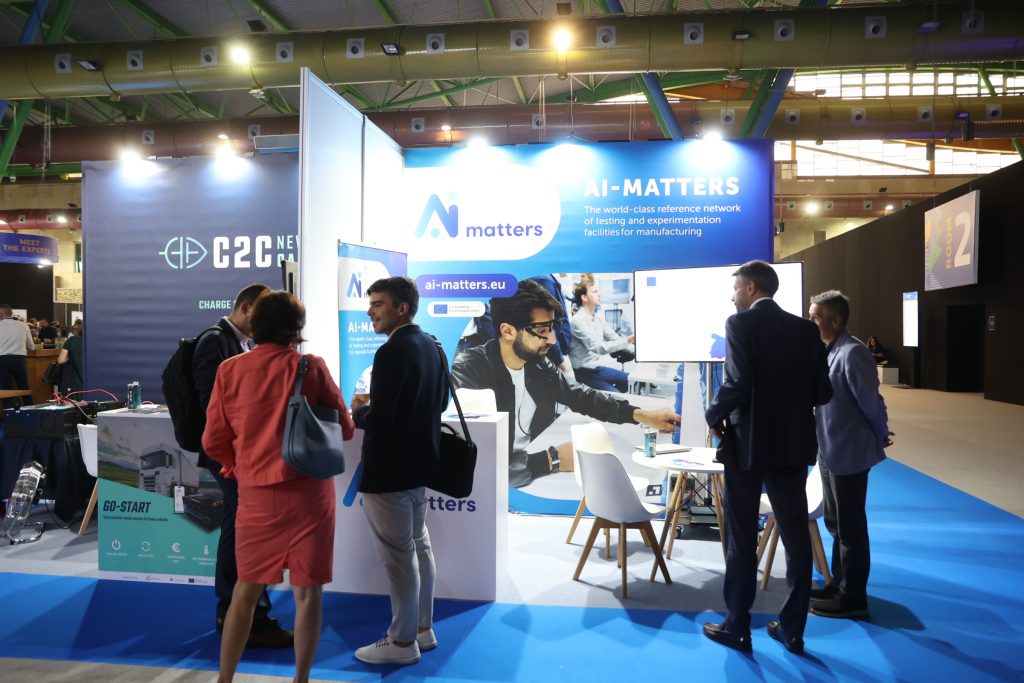

First industrial outreach

Next event:

- Artificial intelligence for a competitive industry, 14 May 2024, Santiago de Compostela.

- Main planned industrial outreach is the 32 BIEMH, Bilbao, June 24.

Other B2B with companies in events such as:

- Industria Conectada (2-3 Oct.) and Industry Days(4-6 Oct.) exhibitions in Málaga.

- 23 CMH The Manufacturing Congress (25-27 Oct.) San Sebastian.

- EBDVF 2023 Data & AI in action: sustainable impact and future realities (25-27 Oct. Valencia)

- MANUFUTURE (upcoming in Nov. 23-24).

B2B with companies in events such as:

- Industria Conectada (2-3 Oct.) and Industry Days(4-6 Oct.) exhibitions in Málaga.

- 23 CMH The Manufacturing Congress (25-27 Oct.) San Sebastian.

- EBDVF 2023 Data & AI in action: sustainable impact and future realities (25-27 Oct. Valencia)

- MANUFUTURE (upcoming in Nov. 23-24).

- Main planned industrial outreach is the 32 BIEMH, Bilbao, June 24.