Labour is becoming increasingly expensive and harder to find. For companies like NFB Coating, this is a harsh reality. “Advanced technology is no longer a luxury, but a pure necessity,” says Richard Kok, Managing Director. Together with Affix Engineering, the company embarked on an AI-MATTERS experiment, facilitated by Brainport Industries, to explore bin-picking with artificial intelligence. Thanks to the support from AI-MATTERS, NFB was able to test whether smart robots can independently pick up and sort metal parts. The initial results? Promising.

“This could be the solution to become less dependent on scarce labour and maintain our competitive edge.”

NFB Coating specialises in painting metal parts for various sectors, such as automotive, agriculture, and medical industries. “Because we do a lot of repetitive work, there are plenty of opportunities to automate,” says Richard. Through a service within the framework of AI-MATTERS, facilitated by Brainport Industries in collaboration with Affix Engineering, the company investigated how AI and robotics can help to automatically pick up and hang parts from a pallet – a technique known as bin-picking.

The collaboration between Affix Engineering and NFB Coating is not new. Affix previously developed a Vision application for visual inspection at NFB. Danny de Greef from Affix Engineering: “That technology turned out to be more widely applicable than initially thought. Thus, the idea to revisit robotics emerged.” Where previous attempts failed due to technical limitations, the combination of Vision and AI now makes a difference. The robot not only recognises how a part is positioned but also where the hook is – even if it is slightly bent or only 1 mm thick. Moreover, this process takes place much faster thanks to new technologies. Parts can be picked up and hung accurately and quickly.

Getting started with a Proof of Concept

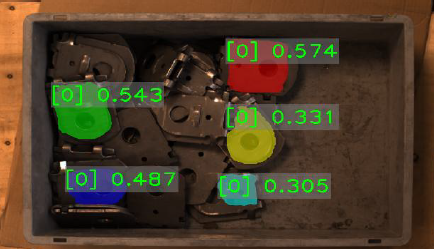

As part of the AI-MATTERS experiment, Affix Engineering helped NFB Coating develop a concrete use case. “We started with a proof of concept for two volume products,” says Danny. “We developed two bin-picking solutions, using two completely different methods to approach and recognise the parts in the bin. This allowed us to demonstrate what is technically possible without NFB having to make large investments immediately.”

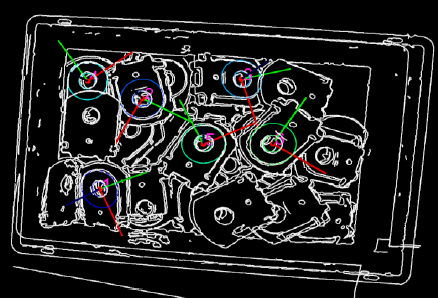

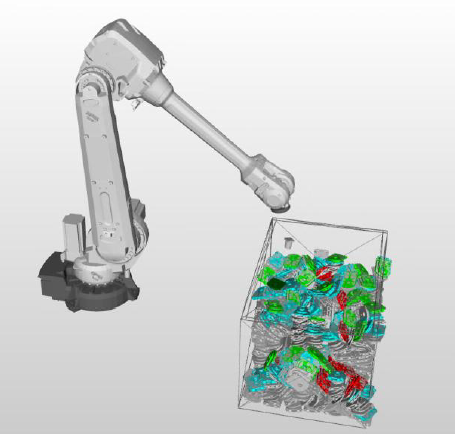

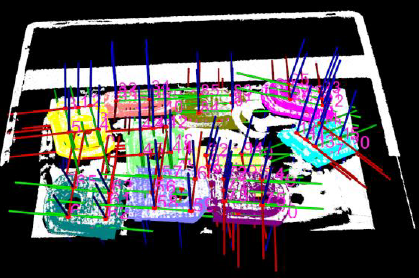

In the first case, small metal parts had to be hung on racks. Two different methods were tested to recognise and pick up parts in full bins, with AI, 3D vision, and deep learning playing a central role. The teams designed and simulated a gripper, optimised it with Twin Pick software, and tested the solution with real robots. They also developed a smart placement strategy using a compact 3D camera and an adapter to hang parts accurately on racks. The proof of concept showed that the solution is technically feasible, although some exceptional situations and accuracy requirements still need to be further developed.

In addition to small parts, NFB Coating also investigated a bin-picking solution for larger metal pieces, which are currently manually picked from bins and placed on racks. The challenge lay in the weight, the close placement of the parts, and the limited space on the rack, requiring precise detection and placement. Using a 3D point cloud, it was determined which parts were free and could be picked up first, based on height differences. The gripper was designed to target existing holes in the part, allowing for a firm and precise grip. A first prototype with 3D-printed fingers and a pneumatic system demonstrated how a more powerful version could safely and reliably take over the heavy work in the future.

Lower costs, better working conditions

Thanks to AI, Affix Engineering and NFB Coating significantly reduced the pick time. This makes the process not only much faster but also economically interesting.

At the same time, automation also offers advantages in terms of labour safety. “Especially with heavier products, it helps to reduce the physical strain on employees. Thus, it cuts both ways: lower costs and better working conditions,” adds Danny.

Low threshold to experiment

Support from AI-MATTERS played a key role. “It lowers the threshold to experiment,” says Richard. “If you do this on your own, you spend a lot of money without knowing if it works. Now we have a solid foundation to build on.”

A first cost calculation is now on the table. “It looks very promising. We are now in the quotation stage and looking at how we can practically set this up.” NFB is also considering aspects such as the supply and removal of racks, nighttime use of robots, and the scale of the project. “It has to be workable, but not too large, otherwise it won’t get off the ground,” says Richard.

Looking to the future: from test to practice

The first step has been taken. The technology works, feasibility has been demonstrated, and the will to move forward is there. Richard: “We are closer than ever to really making robotics a reality.”

The collaboration within AI-MATTERS gave NFB Coating a fresh perspective on automation and the practical application of AI. “When you see that something really works, you dare to invest in it,” says Richard. “We need to seize these opportunities to reduce our labour costs and remain future-proof.”

Danny emphasises the importance of having sufficient time and resources within the programme. “With many subsidies, it is difficult to achieve something concrete. AI-MATTERS provides space to set up a solution that really works in practice.”

According to him, the factory of the future is getting closer: “These kinds of projects help companies take the necessary steps towards the future.”

Is your organization ready to embrace AI?

👉 Discover how AI-MATTERS can help you accelerate innovation and deploy AI solutions with confidence.