Below is just an extract of some of the services available in our catalogue. There are a lot more. Please contact us for more information.

1) proved applications of 5G communication for distributed computing environments ready for AI implementation2) verified performance...

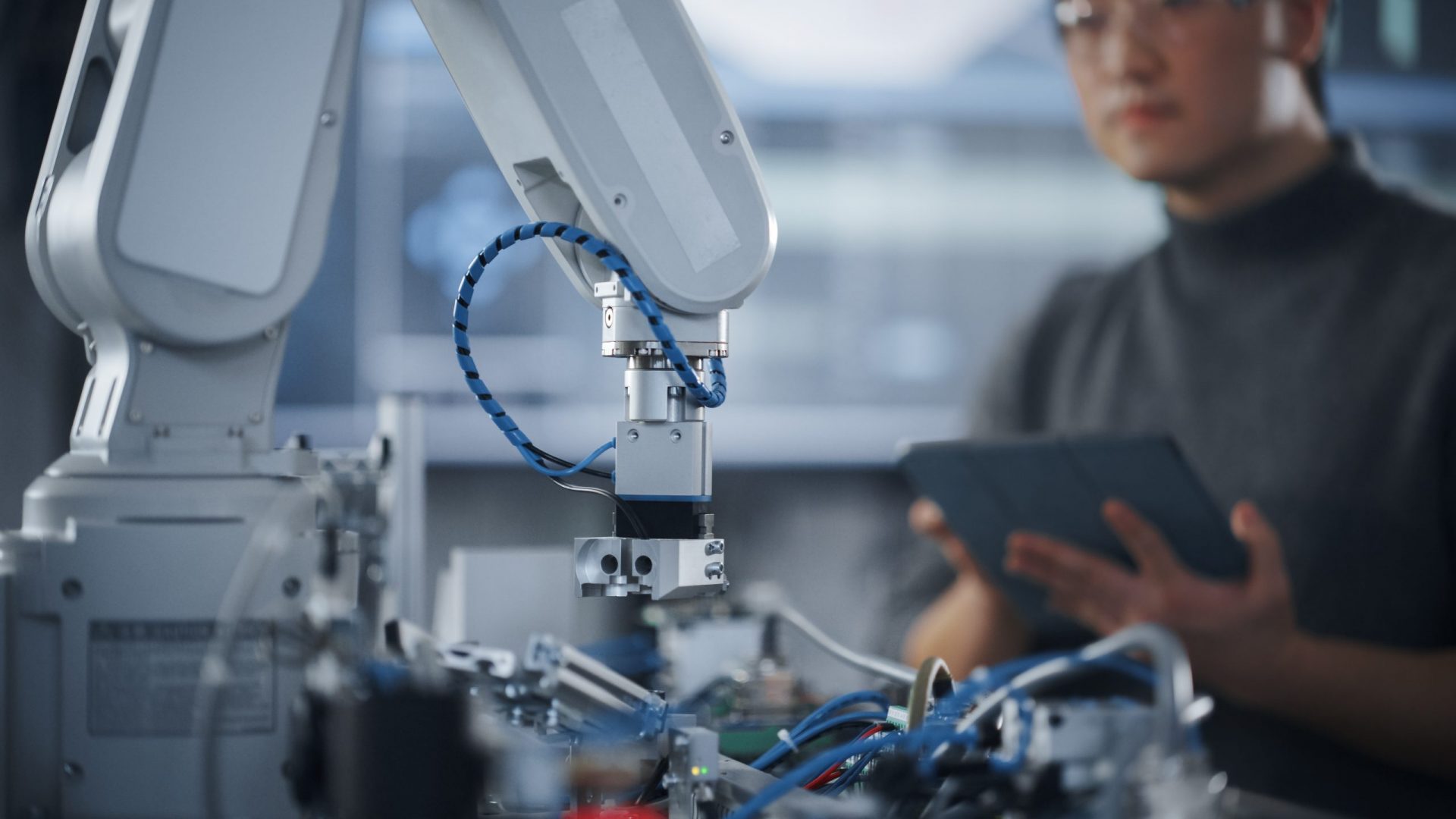

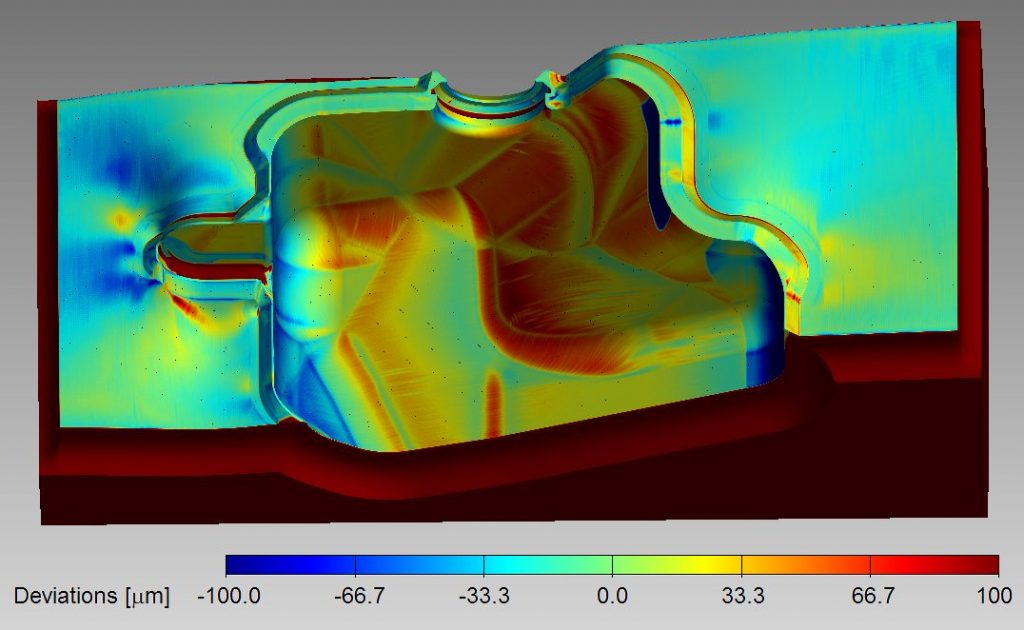

AI-based software suitable for manufacturing...

1) analysis of suitability of different computational architectures for AI implementation2) optimization of AI algorithms implementation...

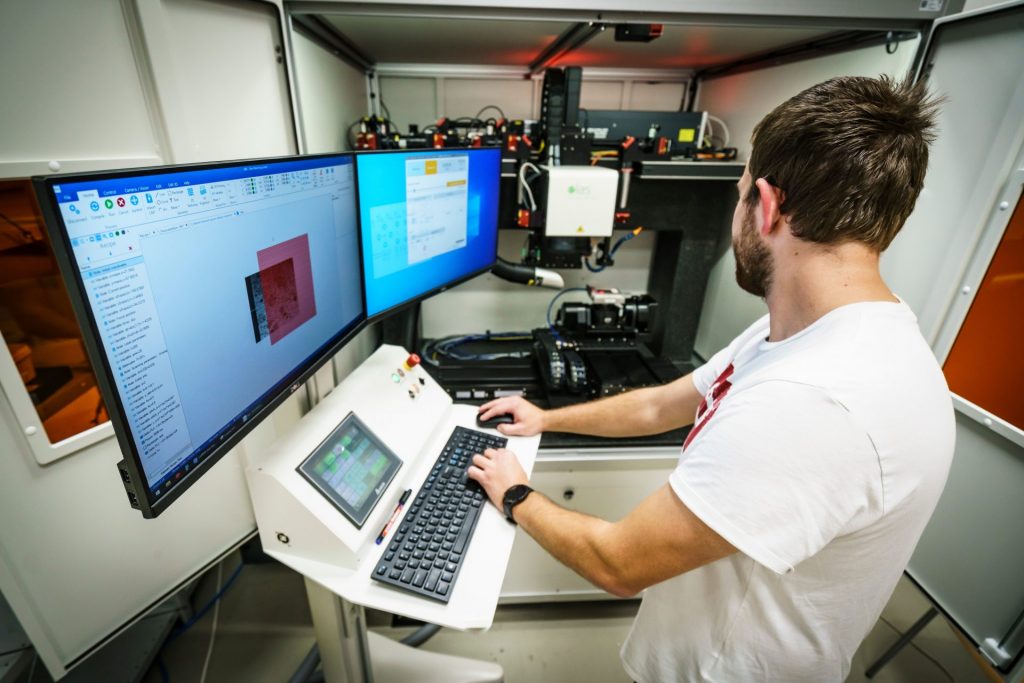

1) Model2) system testing and experimentation3) faster prototyping...

1) Different type of optimalization2) Data processing and collecting for AI assisted decision...

1) Different type of optimalization2) Data processing and collecting for AI assisted decision...

Didn’t find what you were looking for?

AI-MATTERS offers a comprehensive service catalog that is constantly updated to meet the changing needs and expectations of the European manufacturing industry. European companies can use these services, or set up a new service. Contact us for more information.

1) Production optimalisation2) Time saving...

1) Production optimalisation2) Time saving...

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Directorate-General for Communications Networks, Content and Technology. Neither the European Union nor the granting authority can be held responsible for them.

© copyright 2025 AI-Matters

We improve our products and advertising by using Microsoft Clarity to see how you use our website. By using our site, you agree that we and Microsoft can collect and use this data. Our privacy statement has more details.