Tackling Challenges, Embracing Opportunities, and Unlocking the Potential of AI in European Manufacturing

Introduction

In today’s fast-paced manufacturing landscape, the adoption of advanced technologies such as artificial intelligence and robotics has become a strategic need. For CASP, a software firm based in Athens, Greece, specializing in production planning, scheduling, and industrial digital solutions, integrating AI was a crucial step toward enhancing agility, efficiency, and adaptability.

Through its collaboration with AI-MATTERS, CASP was able to validate and refine its AI-driven module for multi-robot task planning and resource orchestration. The partnership significantly reduced reconfiguration times, improved operational reliability, and enabled real-world testing under industry-relevant conditions. This is their story.

The Challenge

Like many organizations pursuing AI transformation, CASP faced specific technical and operational challenges. The core challenge was validating its AI-based solution in a realistic manufacturing environment without the high costs and logistical burden of establishing independent testing infrastructure.

In particular, CASP sought support in ensuring safe and efficient robot task coordination, integrating AI algorithms with existing production logic, and verifying the system’s responsiveness, adaptability, and performance against key industrial KPIs.

The Solution

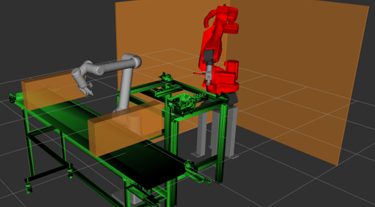

AI-MATTERS, through the Greek Satellite hosted by the Laboratory for Manufacturing Systems & Automation (LMS), provided CASP with access to a state-of-the-art piloting facility. The testbed was equipped with robotic manipulators, industrial sensors, and a digital twin framework enabling full-scale experimentation and validation in a controlled, factory-like environment.

Beyond infrastructure, CASP benefited from close collaboration with robotics and AI experts, who provided technical guidance, integration support, and structured evaluation methodologies. This comprehensive support allowed CASP to benchmark the system’s performance, ensure compliance with industrial standards, and align with ethical and regulatory frameworks, such as the EU AI Act and introduced the use of ALTAI.

The Results

The partnership with AI-MATTERS produced measurable and impactful results:

- Operational Efficiency: System reconfiguration time dropped from 1–2 months to just 5.5 hours for minor changes, and only a few days for complete setup transitions.

- Collision Avoidance: The AI module achieved a 100% success rate, surpassing its initial target.

- Resource Utilization: Efficiency improved to 85%, exceeding baseline expectations.

- System Reliability: The AI-driven planner achieved 96% motion planning accuracy with 100% system uptime during testing.

These outcomes confirmed the scalability, safety, and effectiveness of CASP’s AI module for dynamic, real-time control in complex production environments.

Looking Ahead

For CASP, the collaboration was important for enhancing its AI-driven portfolio. Building on the success of the pilot, the company plans to expand deployment in industrial environments, automate reconfiguration processes, and further enhance real-time AI decision-making capabilities.

Conclusion

CASP’s experience illustrates the impact of AI in European manufacturing and the critical role of testing and experimentation in ensuring successful adoption. By addressing key technical challenges through AI-MATTERS, CASP is paving the way for smarter, more responsive production systems.

Recommendations

“We would strongly encourage any organization, especially SMEs exploring AI in manufacturing, to collaborate with AI-MATTERS. It offers a unique combination of advanced infrastructure, deep technical expertise, and tailored support that is typically out of reach for smaller companies. What sets AI-MATTERS apart is not just access to state-of-the-art facilities, but the structured and hands-on guidance that helps you navigate everything from system integration to regulatory and ethical compliance. The collaboration significantly reduces the time, cost, and uncertainty associated with validating and deploying AI technologies in real-world settings. We were able to prove the maturity of our solution and prepare for broader industrial uptake without having to build our own testing ecosystem from scratch. If you’re developing or integrating AI solutions in manufacturing, this is a valuable opportunity to accelerate your progress with confidence.” (CASP)

Is your organization ready to embrace AI?

👉 Discover how AI-MATTERS can help you accelerate innovation and deploy AI solutions with confidence.