Consortium member

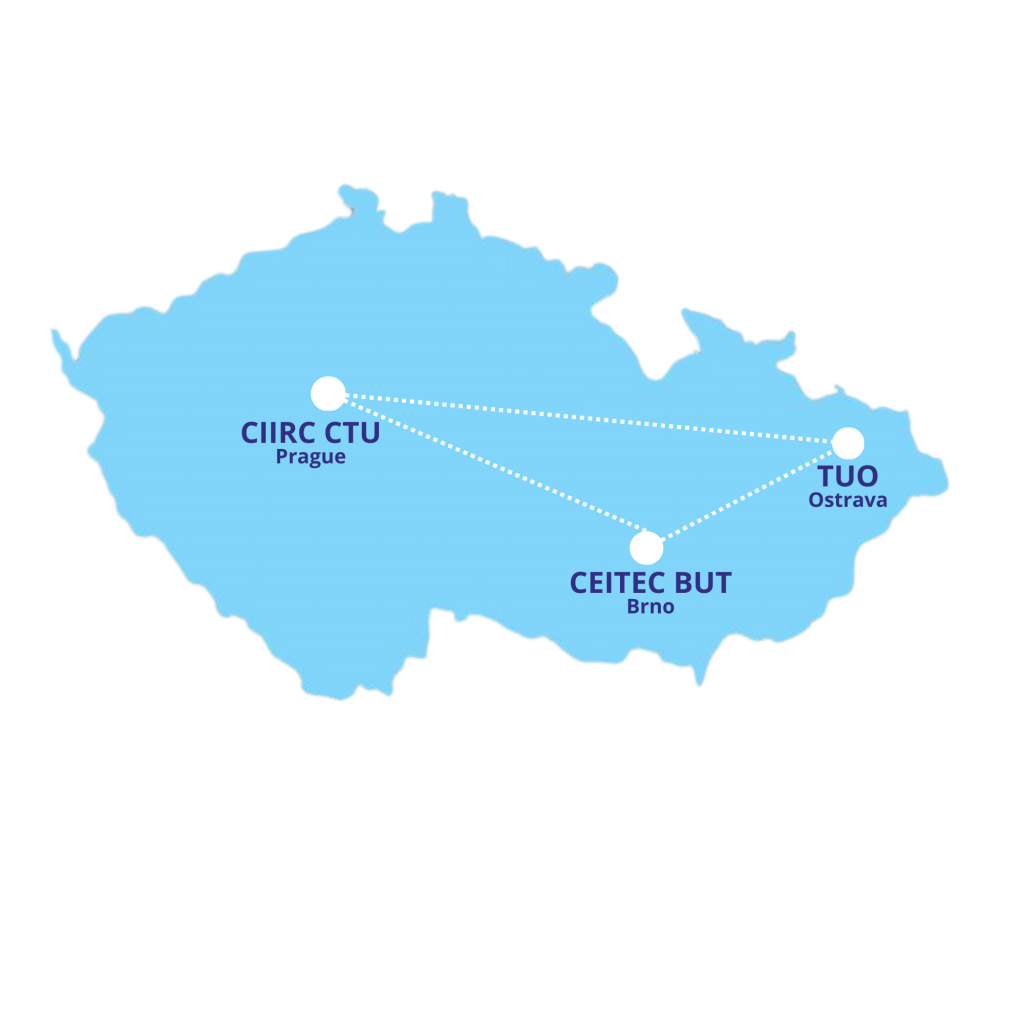

Czech node

The Czech node is composed of 3 industrial testbeds equipped with state-of-the-art technology and unique data sets, each with a strong focus on a variety of AI-driven domains in the field of intelligent robotics and advanced manufacturing.

All testbeds offer a unique technology environment for development, testing, and validation of innovative solutions for an advanced industrial production.

Each entity disposes of research and expert teams with an excellent know-how background from multiple collaboration projects with industry partners.

Node members

CIIRC CTU: coordinator

CEITEC BUT: member

VSB-TUO

Testbed facilities

Node members

Fraunhofer IPA

- Leading the German node

- Part of Fraunhofer organisation

- Fraunhofer is biggest applied research organisation in Germany

- Fraunhofer IPA focusses on manufacturing and automation

Lead contact

Dr. Björn Kahl

bjoern.kahl@ipa.fraunhofer.de

Institute of Electrical Energy Conversion (IEW)

- Part of University of Stuttgart

- Research focus on electrical machines and contactless energy transfer

- Applications in the areas mobility, medical technology and industrial applications

Lead contact

Urs Pecha

urs.pecha@iew.uni-stuttgart.de

Research Campus ARENA2036

- Research campus with over 50 partners from industry and science on one platform

- Focused on research in production and mobility

- Establishing services with robotic infrastructure for AI applications

Lead contact

Frederik Wulle frederik.wulle@arena2036.de

Physikalisch-Technische Bundesanstalt (PTB)

- National metrology institute

- Founded 1887

- Today: 3 sites, staff: ≈ 2000

- Agency of Federal Ministry for Economic Affairs and Climate Action

- Division Precision Engineering focus: manufacturing metrology

- Virtual instruments (dig. twin), Testing of algorithms for CMM

Lead contact

Dr. Harald Bosse harald.bosse@ptb.de

Focus & Selected Domains of Expertise

- Data Life cycle

IoT and data analytics in data acquisition, data storage, big data. Edge computing, data privacy and sovereignty. - Production processes

Additive manufacturing, process and machine diagnostics, process optimization. - Digital Twin & Digital Shadow

Matching of physical systems and simulations, virtual commissioning, dynamic models of machines. Predictive maintenance. - Smart Factory and Distributed Production

Automatic production planning, material flow planning, modular and flexible production, logistic operations, production as a service. - Advanced energy systems

Optimization of production processes with interconnection of available energy sources. Electricity distribution systems with the involvement of various sources of green energy.

- Flexible production systems

Additive and subtractive technologies, robotics, mobile manipulators, UGV, UAV. - Human-Machine-Robot Cooperation

AR / VR technology, Precise localization and navigation in an industrial environment. Remote inspection, visual telepresence.

- Machines & Mechatronics Systems Diagnostics

Sensors for diagnostics and predictive maintenance, vibrodiagnostics, acoustic holography, acoustic emission. Advanced automation and AI applications.

- Advanced actuators

Advanced actuators (rotational and linear) for industry, powertrains for electromobility, fail-operational drives, drives advanced control, diagnostics, monitoring.

- IoT systems, industrial 5G communications.

- HPC, edge-computing, edge-continuum.

- Advanced industrial technologies

Interoperability, virtualization technologies and digital twin, services oriented cyber-physical systems, virtual commissioning, distributed control systems, real-time work, AR / VR. - Industrial robotics

Intelligent robotics for industrial use incl. precise measurements, bin picking etc. - AI in Manufacturing

Data processing and diagnostics, Data analytics, ML and AI application, optimization issues. Extensive data repositories for process and diagnostic data. - Autonomous vehicle systems

HIL-PIL-SIL modeling, simulation and testing of electronic systems in a component or integration assembly.

Functional Safety and Automotive Spice Department.

Unit for testing vehicles with conventional, electric or hybrid drive.

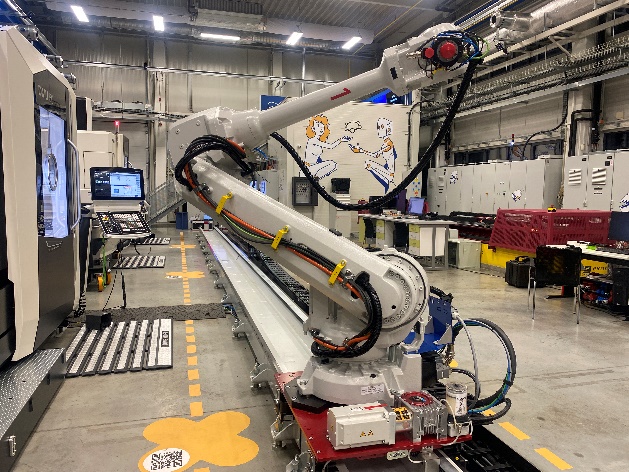

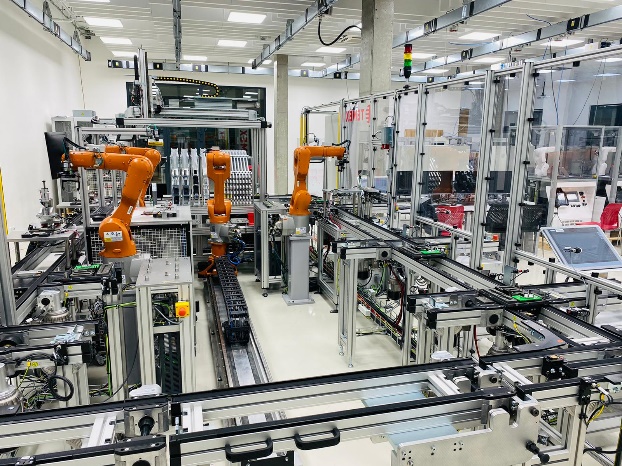

Selected technology equipment

- Full-featured 5G Stand-Alone private campus network (installed in all three testbeds in cooperation with T-Mobile CZ) for data transmission to an application/edge server with guaranteed latency and bandwidth. The server’s high computing power can be used for industrial computer vision applications or other neural network deployments. It opens new activities in industrial wireless communications including wireless automation networks.

- Robotic cells and modules for flexible production, pick & place operations, systems for machine vision and other applications

- Flexible production and assembly lines with several technologies and conveyors

- Industrial robot areas with production machines for machining and hybrid processes and process optimization

- Various flexible settings of collaborative robots for human-robot interactions and assembly tasks

- Systems for machine vision

- Systems for data exchange between individual machines and superior systems

- Multi-axis motion systems and robotic arms, automatic loading station

- Automatic warehouses with fleet of mobile robots and vehicles for integrated intralogistics

- Highly professional 3D Printing centres for additive manufacturing from plastics and metals, incl. 3D robotic printing – for prototyping, low-volume manufacturing runs, or customized parts

- Smart Grid Lab incl. the connection to the photovoltaic system

- Metrology laboratories with automated 3D scanning systems for precise measurement

- Subtractive and hybrid manufacturing, laser technologies and welding solutions

- Dynamometers (rotational and linear), actuators and traction drives

- Industrial manipulators, cobots, mobile robots, walking robots

- AR/VR technology, Virtualization technologies

- Precise localisation system