High-frequency and high-accuracy measurements can help to understand flexibibity/modeshapes of flexible products, or help to understand...

To minimize time spent in programming how to perform a task, the user can teach the...

Experiment with one or two Panda cobots to investigate if they can add value in the...

Experiment with mobile platforms that might be used in a manufacturing hall to get products from...

Technology evaluation, demonstratror...

Technology evaluation, demonstratror...

Demonstrator...

Technology evaluation...

Technology evaluation, demonstratror...

Technology evaluation...

Demonstrate that application of AI reinforcement learning can greatly improve efficiently and reduce costs as compared...

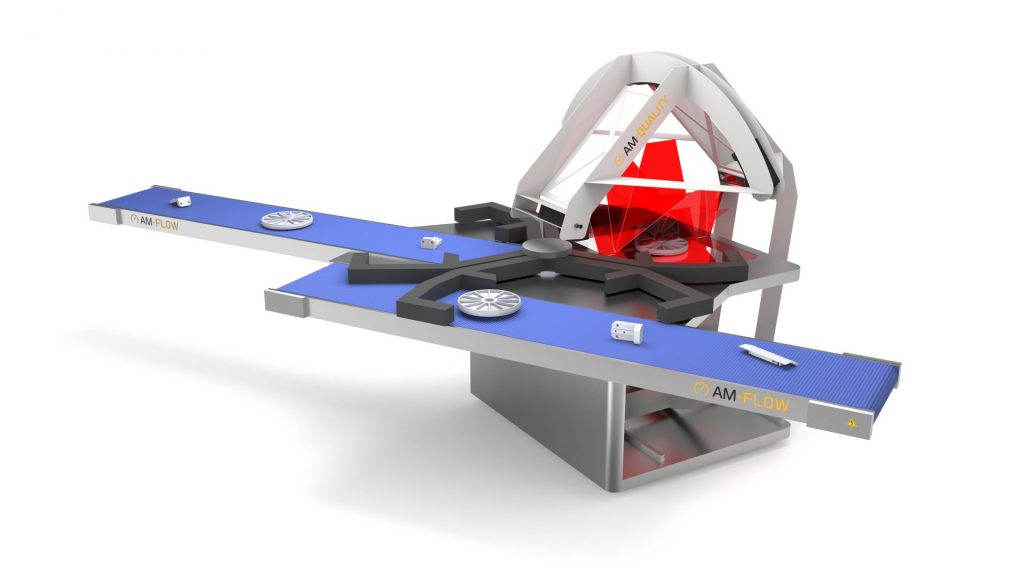

Evaluation of ability to leverage existing technology for high variability of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

Technology evaluation...

Demonstrate that the existing technology can be leveraged (adapted) to be used for different objects...

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Directorate-General for Communications Networks, Content and Technology. Neither the European Union nor the granting authority can be held responsible for them.

© copyright 2024 AI-Matters