The service must enable the company to initiate further test or experimentation services...

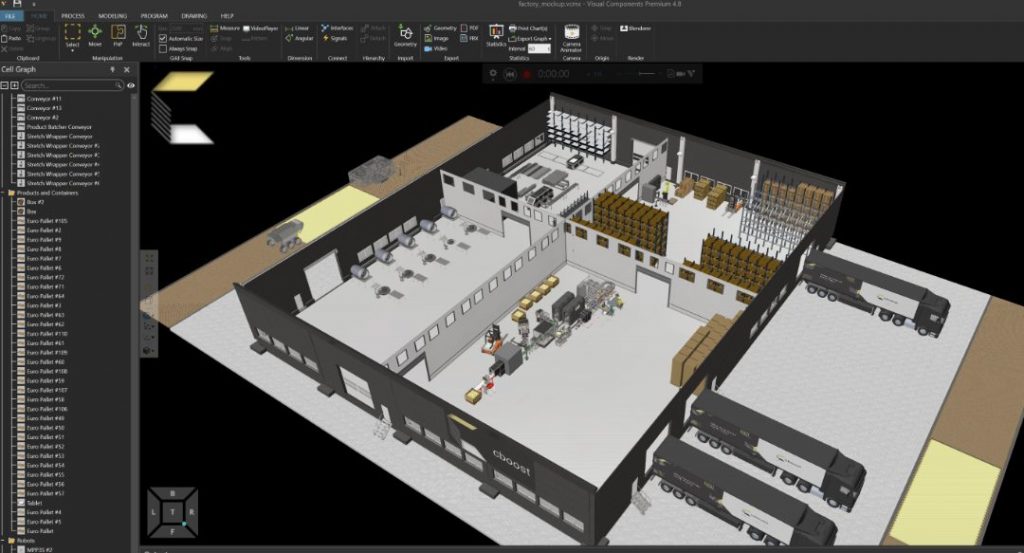

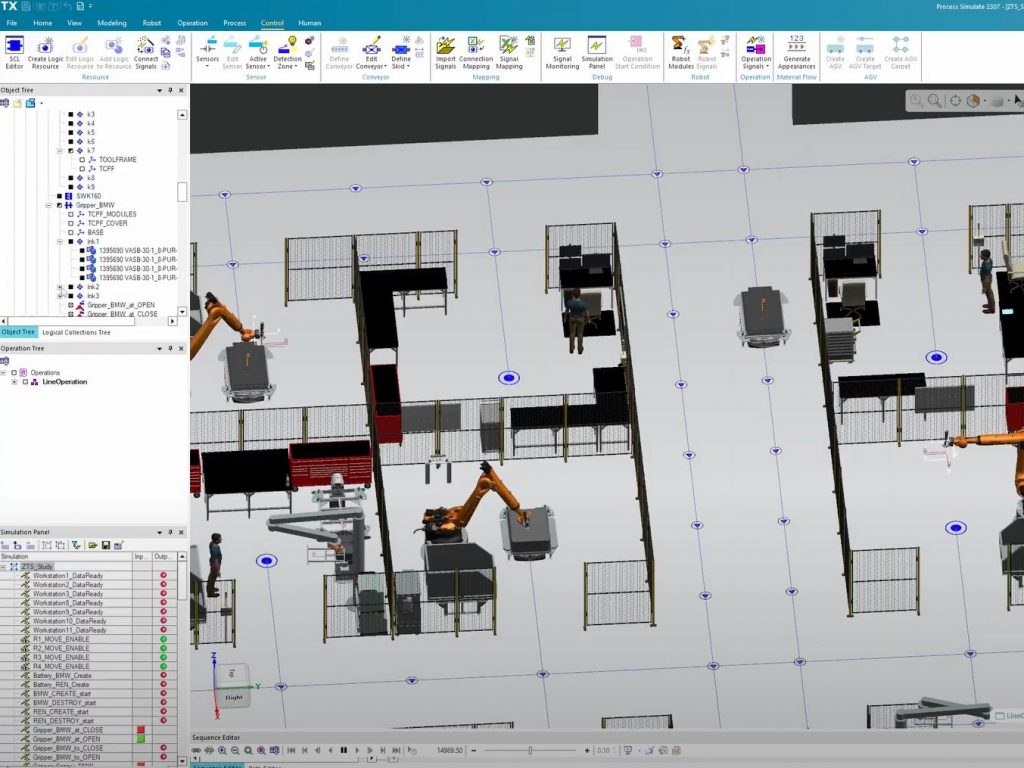

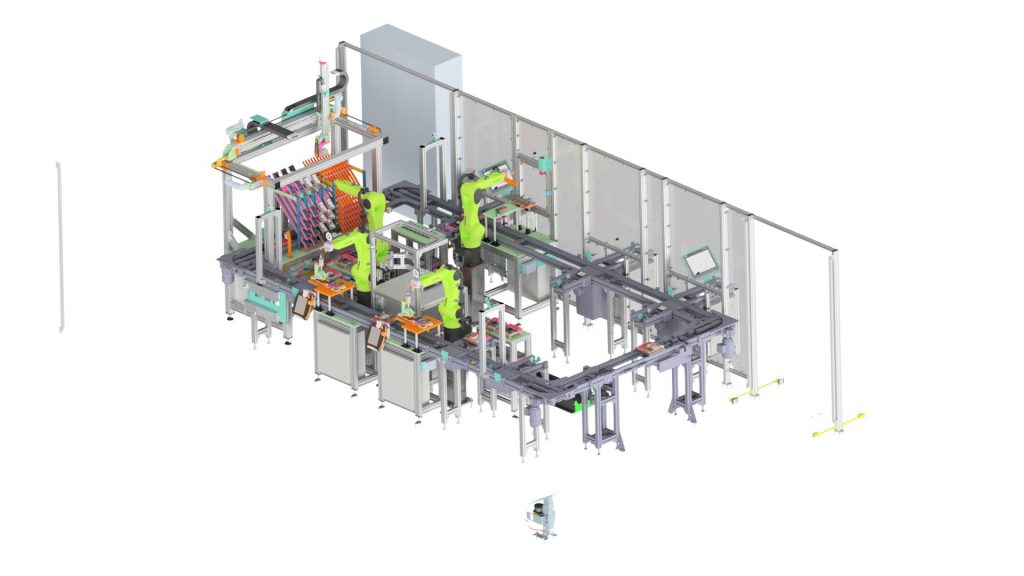

1) optimize production lines reconfiguration by virtual commissionning 2) optimize use and maintenance of an industrial...

1) optimize the conception of production lines, increase availabilty of production lines, optimize the orchestration of...

Guide the choice of network infrastructure before investment Demonstrate achievable performances...

Enable a system or a robot to make a decision and act in a given situation...

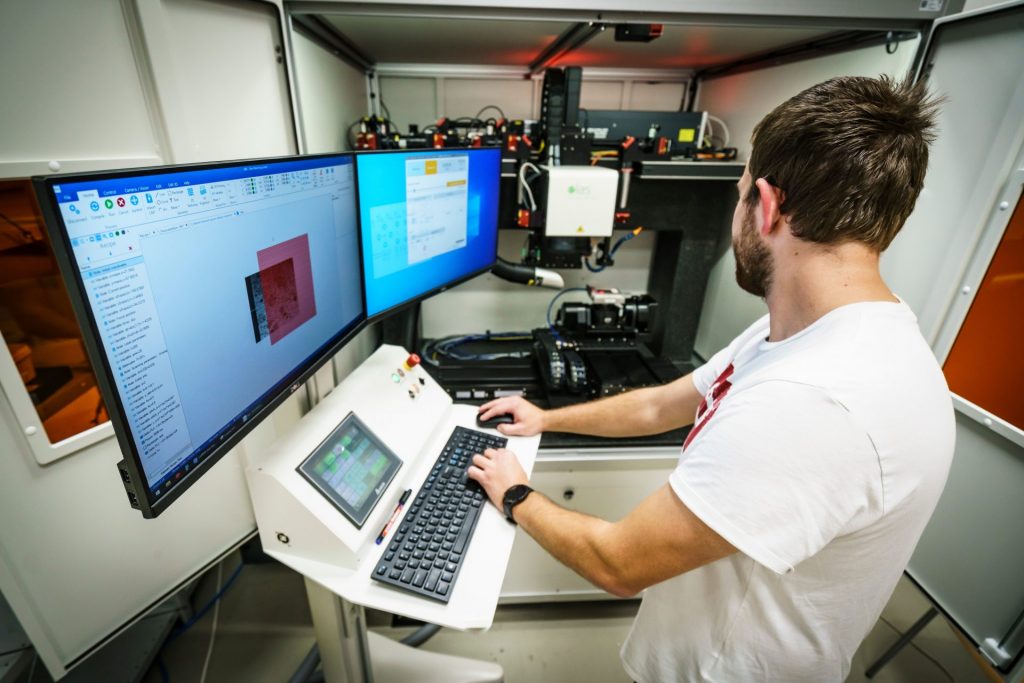

Technology evaluation, demonstratror...

Technology evaluation, demonstratror...

Technology evaluation...

Demonstrate that application of AI reinforcement learning can greatly improve efficiently and reduce costs as compared...

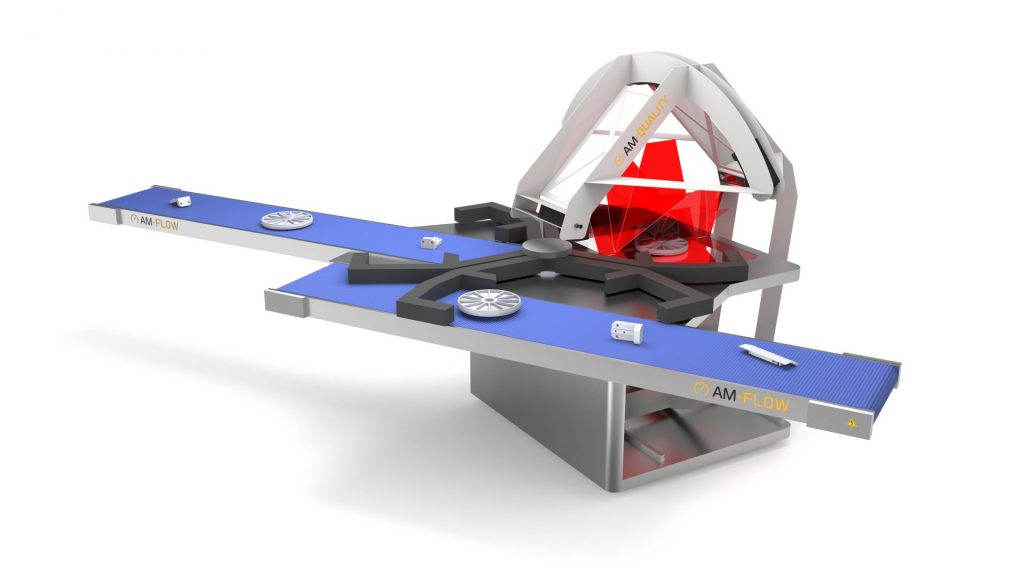

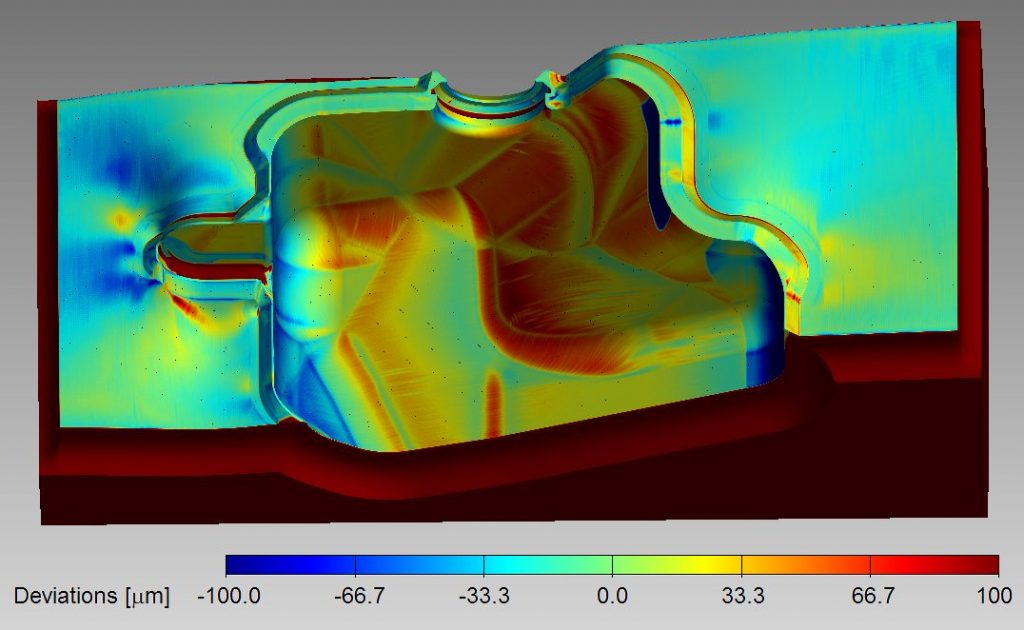

Evaluation of ability to leverage existing technology for high variability of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

- Evaluation of ability to leverage existing technology modules to cope a higher variety of parts...

Technology evaluation...

1) Production optimalisation 2) Time saving...

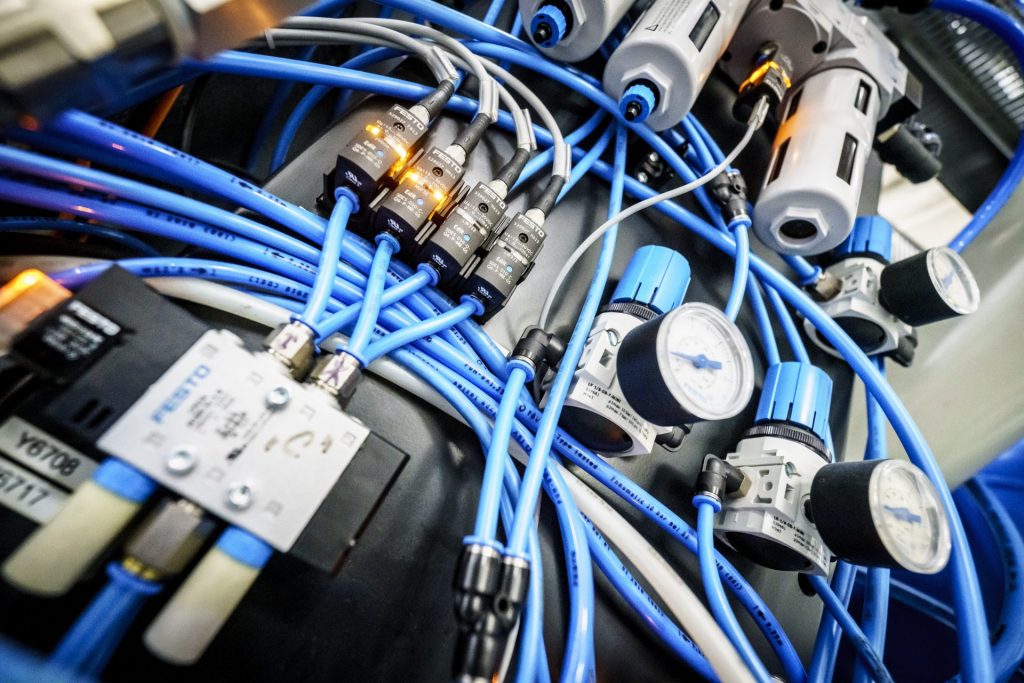

1) Data collecting 2) Quality prediction 3) Production prediction 4) Maintenance planing...

1) Replacement of physical systems 2) digital twin preparation 3) independent verification...

1) Different type of optimalization 2) Data processing and collecting for AI assisted decision...

1) Model 2) system testing and experimentation 3) faster prototyping...

1) Different type of optimalization 2) Data processing and collecting for AI assisted decision...

- Validation of system performance - highlighting weakness and suggesting possible improvement...

1) Model 2) system testing and experimentation 3) faster prototyping...

1) Production optimalisation 2) Time saving...

- Validation of system performance, - highlighting weakness and suggesting possible improvement...

AI-based software suitable for manufacturing...

1) Production optimalisation 2) Time saving...

1) Different type of optimalization 2) Data processing and collecting for AI assisted decision...

- Validation of system performance, - highlighting weakness and suggesting possible improvement...

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Directorate-General for Communications Networks, Content and Technology. Neither the European Union nor the granting authority can be held responsible for them.

© copyright 2024 AI-Matters